Aeroflex Advantages

The closed cell structure of Aeroflex provides many advantages over most rigid insulations such as:

Temperature Range

Aeroflex standard enhances enegy-saving and prevents condensation when used in operating temperatures down to -57 ํC and prevents heat loss up to125 ํC. However, for higher temperature up to 150 ํC, Aeroflex-HT is recommended which is suitable for low pressured steam application, but not suitable for electric heater and radiator system. Within these recommended operating temperatures, it will not affect the thermal efficiency of Aeroflex.

Flame & Smoke Proof

Aeroflex standard products have been specially formulated to meet and exceed the international fire standards such as ASTM E84, UL94, JIS K 6911, EMPA, IMO A653 and other standards. For other specific international fire standard, Aeroflex also offer Aeroflex-EP for FM approved insulation product. The products have low smoke density while burning and unlike other thermoplastic materials, Aeroflex will not melt nor drip flaming balls, therefore, it will not cause flame transfer.

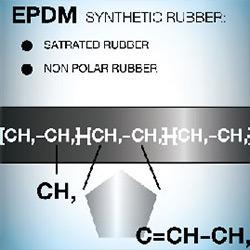

Non-Polar Material

Aeroflex is made from EPDM Synthetic rubber. EPDM rubber is classified as Non-Polar material which is highly water resistant while NBR/PVC is classified as Polar, which slowly dissolves in water and causes surface deterioration. Meanwhile water is also polar material, so continuous contact with condensate water as water vapor damages NBR/PVC insulation much faster than EPDM based insulation.

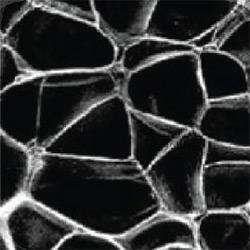

Water Absorption & Moisture Permeability

The closed cell structure protects against moisture and assure very low water absorption which can eliminate the need for a water vapor barrier in the most applications. However, under severe condition of high humidity (90% RH up), high temperature (40 ํC up), low ventilation area like tunnel or gutter and also direct to sun light, metal or polymeric jacketing is recommended to use as additional water vapor barrier and greater protection against severe condition.

AEROFLEX Outstanding physical properties

Closed Cell

Wide Application Temprature

Fire and Smoke Safe

Low Thermal Conductivity

Weather Resistance

Low Density

Low Water Absorption

Non Corrosive

Environment Friendly

Wide Size Range

Non Polar

International Compliance

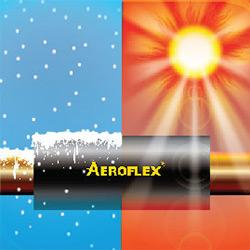

Chilled Water & Refrigeration System

AEROFLEX EPDM closed cell elastomeric thermal insulation is a superior insulation for cooling systems that function at below ambient temperature for energy saving by retarding heat gain and also preventing condensation on chilled water and refrigeration lines. Aeroflex also prevents the water pipes from freezing when ambient temperature is below sub-zero point. In areas with high humidity, condensation problems often occur on chilled water pipelines in central cooling systems. The condensation does not only damage ceiling, carpet and other furniture but also waste energy because of higher heat gain on chilled water pipes.

Water Vapor Permeability (g/Pa.s.m (x 10-10))

- Aeroflex : The closed cell structure density 48-80 kg/m3

- Polyurethane Foam : The semi closed cell structure density 32-64 kg/m3

- Polystyrene Foam : The interconnecting cell structure density 16-32 kg/m3

- Fiberglass : The open cell structure density 32-64 kg/m3

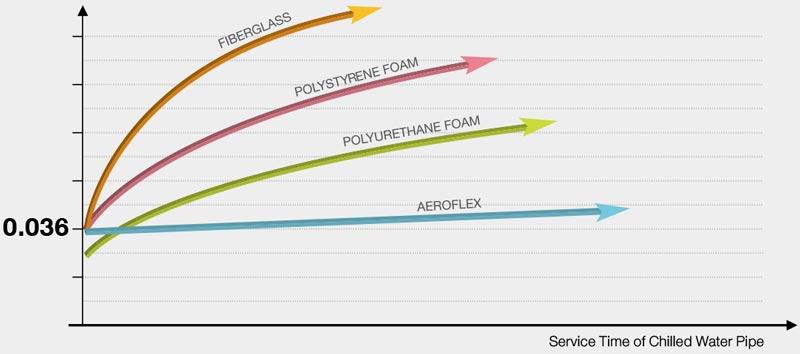

K. Value (Thermal Conductivity) [W/m.K]

AEROFLEX is EPDM-based material with fine cell structure containing dry air (mainly nitrogen gas) which is high resistant to convection heat transfer, and with thousands of cell walls acting as multi-layer water vapor barrier to retard water and moisture penetration, resulting in low and stable thermal conductivity throughout service time. Aeroflex has been widely used in chilled water and refrigeration systems due to the following superior characteristics:

- Great resistance to water vapor penetration and very low water absorption.

- Low and very stable thermal conductivity (K. Value).

Hot Water System

AEROFLEX elastomeric thermal insulation is very effective in reducing heat loss on hot water pipings, liquid heating and dual temperature piping in hospitals, hotels, residential buildings, industrial plants, etc. It’s also used on central liquid heating system to heat private houses and public buildings. For higher performance in heat resistance and outdoor application, AEROFLEX-HT provides exceptional ozone, ultraviolet and weather resistance, also used for solar-heating and steam-heating applications with service temperature up to +150 ˚C. No danger of fibrous material when installed in place where hygiene is vital. Aeroflex is manufactured from synthetic polymers which contain no asbestos or fibrous material. The is one of many reasons why Aeroflex is widely selected as replacement for fibrous material like fiberglass or rock wool used in hot water and low pressured steam pipeline. The closed cell structure and superior elastomeric properties provide the following advantages:

- Service temperature up to +125 ˚C for Aeroflex Standard and up to +150 ˚C for Aeroflex-HT

- Outstanding ultraviolet and weather resistance when used outdoor

- Very stable thermal conductivity value throughout service life

- Very low water absorption

- No jacket is necessary even for outdoor piping, unless long term direct contact to sunlight jacketing or protective coating are recommended Flexibility for easy installation